Table Of Content

Zuken aims to empower engineers with vital tools to innovate and adapt, enabling modern conveyor system design and paving the way for the next generation of technology. In this post, we’ll explore conveyor technology, its significance across various industries, current trends, and how Zuken’s cutting-edge tools are shaping the future of conveyor system design. These are mainly termed baggage handling conveyor systems which are generally used in airports for transporting luggage from ticket allotment counters to the locations where bags are loaded into planes. These are also used for the transportation of luggage from one plane to another plane.

Conveyor Design: Best Practices and Tips

Not only does this reduce equipment costs, but it reduces downtime due to jams and stoppages. Design manuals will provide a general idea of usable belt widths for the calculated cross-section, and they often make suggestions for safe belt speeds based on dust, noise, and wear. Both of the major conveyor design methodologies, CEMS and DIN recommend derating capacity by 10 to 15% to handle surge loading and reduce spillage.

Design Considerations for Maximum Conveyor Efficiency

A conveyor more or less acts as a central nervous system for operations that receive, handle, store, distribute, manufacture or ship products. Selecting the right conveyor system can be challenging for warehouse managers and other stakeholders due to the several conveyor types and hundreds of possible configurations to choose from. Chain on Edge Conveyors (COE)A chain on edge conveyor (COE) is a single strand chain conveyor (SSCC) capable of flexing along the horizontal axis and making horizontal turns and vertical curves. Various types of twists and turns make COE more versatile than traditional chain driven conveyors.

What are conveyors and what are they used for?

By implementing a conveyor belt system with food-grade materials, easy-to-clean surfaces, and gentle product handling features, the facility achieved a 30% reduction in product waste and improved overall hygiene. The optimized conveyor belt design not only enhanced production output but also ensured compliance with strict food safety regulations. These three factors are just the tip of the iceberg when it comes to designing conveyor belts for maximum production output. Additional considerations include belt width, speed, incline/decline angles, and transfer points. Each of these factors requires careful analysis and customization to match the specific requirements of the industry and production process. The belt is placed in a loop between two pulleys and is supported on either rollers or a metal slider pan—if the loads aren’t too heavy.

Stainless Steel Conveyors

woojin park's detachable chairs infuse new value to conveyor belts - Designboom

woojin park's detachable chairs infuse new value to conveyor belts.

Posted: Thu, 13 Oct 2022 07:00:00 GMT [source]

They help in completing various tasks, and by automating them, you can gain the extra benefits of flexibility and safe procedures. Additionally, they support improving the efficiency and cost-effectiveness of your processes. Conveyor systems can be used in a wide range of industrial sectors for a variety of processes, including production, packaging, and even delivery. Paternoster ConveyorsPaternoster conveyors, also known as platform conveyors, are a vertical conveying system that uses platform carriers attached to a chain drive.

Instead of having a pulley system that pulls items along, the chain conveyor uses a towing system that pulls the steps in an upward or downward motion. Automation helps in the identification of significant product flaws like faulty components and unwanted metal, among others. Conveyor solutions aid in orienting products for the subsequent assembly or operation, preventing time from being lost to product repositioning. A friction conveying system is a safe alternative to power and free systems.

It’s a good option if you have little to no interest in speeding up or slowing down the conveyor. He started with Design News in 2002 as a freelancer and hired on full-time in 2011. Without further ado, let’s explore factors to consider when evaluating and selecting the right conveyor system for your operation. By submitting, you consent to DCS processing your information in accordance with our Privacy Policy.

Pallet Conveyors

In this mechanism, the belt pulleys hold the belt, and the bearing holder set is mounted on a roller plate. The adjustment mechanism ensures the belt is parallel to the roller plate and is made up of a bracket for an adjusting screw and a position adjusting screw block. A chain-driven power transmission system is used to transmit power from the gear head induction motor to the belt pulley. Conveyor systems transport materials, products, or goods from one location to another within a facility.

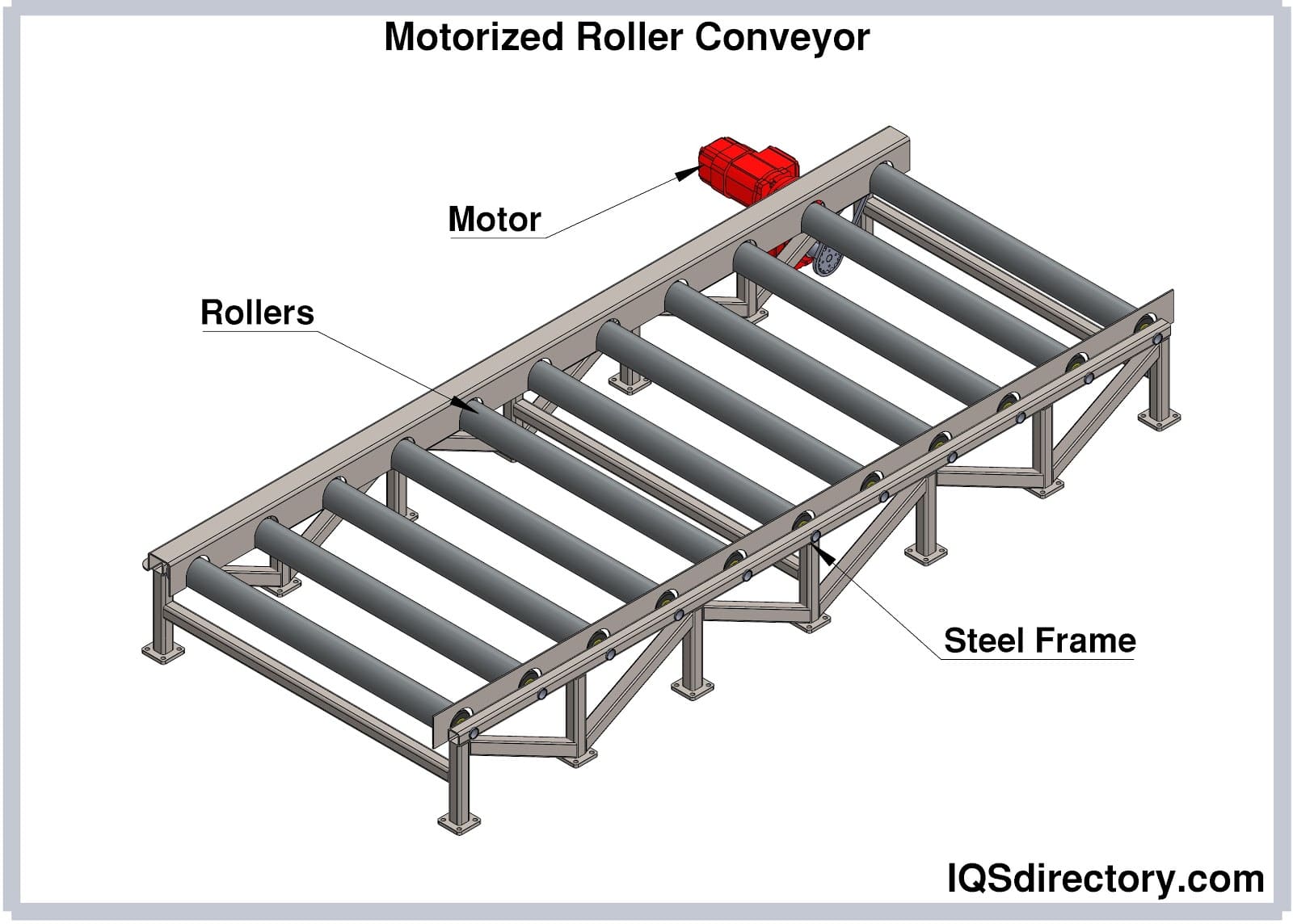

Main Conveyor Types You Need to Know

In these types, one or more of the pulleys is powered by a motor that moves the belt. This has led to the automation of belt cleaners so they can be remotely monitored and adjusted. Usually, a project starts with a general idea of the material to be moved, the design capacity, the conveyor path, and the space for installation. Not understanding the practical conveying limits for these four basic inputs is often the root cause of poor performance, unplanned downtime, safety incidents, and even catastrophic failure. To maintain a high-quality conveyor belt, regularly inspect for debris or damage. This applies to the track, rollers, or pulleys that could affect its performance.

Conveyor systems are designed through a meticulous process that involves understanding the specific needs of the operation where they will be used. The design process begins with an assessment of the materials or products that the conveyor will transport. This includes considering the size, weight, and type of materials, as well as how quickly and in what volumes they need to be moved. This software helps in calculating critical parameters such as belt speed, belt width, load capacity, and motor power requirements.

A conveyor system increases productivity, improves ergonomics, reduces product damage and makes for better access to materials and fewer workplace hazards. A conveyor system is a mechanical device that moves materials from one place to another. These are common in the material handling and packaging industries for moving bulky or heavy items. They can minimize human error, lower workplace risks, and reduce labor costs. Additionally, the application of AI and Machine Learning is playing a pivotal role in modern conveyors.

No comments:

Post a Comment